BullseyeBore CORE SUPPORT

quick start guide: troubleshooting

For models CR1-100, CR1-101, CG1-100 and CG1-101

NOTE: Appearances, features, and functionality may vary from the written instructions based on product and labeling updates. Please refer to this website for the latest information and additional details.

TROUBLESHOOTING

BULLSEYEBORE CORE DOES NOT POWER UP OR THE LASER IS INTERMITTENT OR FLICKERS DURING USE.

INITIAL CHECKS: Ensure you've followed the online Setup section of the Quick Start Guide correctly. Verify you're using new batteries inserted in the proper orientation. If problems persist, you may need to inspect the battery contacts.

ROOT CAUSE: Power issues are commonly caused by bent, compressed, or distorted positive battery contacts that do not properly touch the side of the battery (causing intermittent or no electrical continuity). This can happen due to impact damage, using oversized batteries, or normal wear from extended use. The good news is this is typically easy to fix with basic tools!

INSPECTION: Remove the housing to access the battery compartment. Look carefully at both vertical positive battery contacts that touch the sides of the batteries. Check if either or both contacts appear bent, distorted, or misaligned. Here are two common issues and solutions:

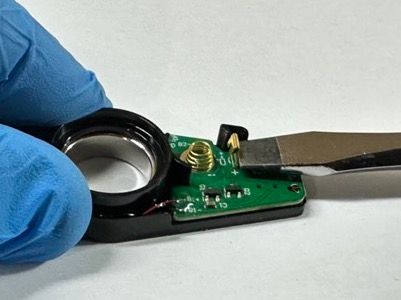

ISSUE #1: Bent Long Vertical Battery Contact Arm

Problem: The long vertical arm of the positive battery contact is bent backward, away from the battery, causing poor or no contact with the battery.

Solution: Use a small flat screwdriver or the flat front of a closed pliers. Gently bend the connector back toward the battery. CAUTION: Apply gentle, steady pressure - pushing too hard may break the connector! The goal is to bend the vertical arm back into the correct position which can be either perpendicular to the PCB or slightly angled toward the battery.

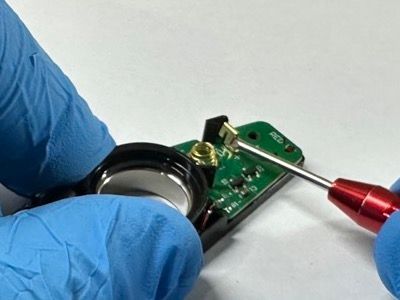

ISSUE #2: Bent or Compressed Battery Contact Short Arm

Problem: The short curved arm of the positive battery contact is bent away from the battery or compressed toward the long vertical arm. In this example, one of the two "prongs" is bent towards or compressed against the long vertical arm, but its possible for both to be bent towards or compressed against the long vertical arm.

Solution: Use a small flat screwdriver or pliers. Carefully bend the short arm back toward its proper position. CAUTION: Use minimal force to avoid breaking the connector! The short arm should be positioned to maintain consistent contact with the battery.

After application of one or both of these solutions, reassemble the unit completely with the batteries installed properly and test. The repair is successful when the laser functions continuously without flickering or intermittent operation.

New Paragraph

THE HOUSING IS DIFFICULT TO REMOVE. HOW DO I REMOVE THE HOUSING FOR A BATTERY CHANGE?

Since BullseyeBore Core is built with tight tolerances, the housing can be difficult to remove from the inner body. The easiest way to separate the housing from the inner body is by simply removing the screws, placing the unit on a flat ferrous surface, and gently pulling off the housing. BullseyeBore Core's magnet should stick to the flat ferrous surface and allow the housing to be removed easier. For specifics on this, please see step #2 in the online Setup section of the Quick Start Guide.

New Paragraph

THE LASER BEAMS ARE DIM.

When the batteries become depleted the laser shifts to a very low power mode and becomes dim. A dim laser requires replacement with new batteries. For specifics on battery replacement, please see the online

Setup section of the Quick Start Guide.

New Paragraph

BULLSEYEBORE CORE DOES NOT APPEAR TO SECURELY CONNECT TO THE FACE OF MY DRILL CHUCK.

BullseyeBore Core and the accessories were designed with the goal of working with most common standard electric drills and drill chucks, but due to the vast number of drill and chuck combinations, some careful user testing is required prior to use. Please note that some drill chucks may not operate with BullseyeBore Core due to their size, shape, or material.

Before using BullseyeBore Core in a drilling operation for the first time, it is recommended that you perform rotational testing within a safe and small enclosed area. For more guidance on rotationally testing BullseyeBore Core with a given drill, please see the Rotation Testing item of the Safety Guidelines.

For more guidance on drill and drill chuck compatibility, please see the Drill Compatibility section in the online BullseyeBore Core FAQ.